Low Voltage Power Conditioning

|

PCS100 UPS-I

Designed for commercial and industrial applications, Hitachi Energy’s PCS100 industrial UPS has power ratings from 150 kVA to 3 MVA. The Hitachi Energy PCS100 UPS-I is a high performance, high efficiency UPS system that ensures protection from power quality events, enabling continuous power supply to modern industrial processes. Designed for industrial applications (tooling, machinery, robotics, drives and motors), Hitachi Energy’s PCS100 Industrial UPS provides a seamless power supply, eliminating downtime. A lower total cost of ownership than alternative solutions, makes the PCS100 UPS-I a high performance, high efficient UPS system. Voltage sags, surges and short outages are common events that often cause electric and electronic equipment to malfunction. When such events occur in critical control operations, they can cause the complete shutdown of a facility. The PCS100 UPS-I is designed to solve these problems. It is a robust single conversion UPS and is used to protect sensitive loads from sags, surges and outages using ultra-capacitor or battery energy storage. |

|

The PCS100 AVC (Active Voltage Conditioner) is an inverter based system that protects sensitive industrial and commercial loads from voltage disturbances.

PCS100 AVC provides fast, accurate voltage sag and surge correction as well as continuous voltage regulation and load voltage compensation without the need for energy storage. It has been optimally designed to provide the required equipment immunity from the level of voltage sags expected on the AC supply network. The PCS100 AVC is available in load capacities of 150 kVA to 2.4 MVA. The PCS100 AVC offers an operating efficiency exceeding 98 percent and has an extremely fast response to three-phase sags down to 30 percent, and single-phase sags down to 0 percent on the AC supply network. Standard models offer enhanced performance allowing correction of voltage sags and surges. The PCS100 AVC model provides continuous regulation within +/-10 percent of the nominal mains voltage and also remove voltage unbalance from the supply. |

|

Power Factor Correction - Activar

This system is a cost-effective alternative to electro-mechanical power factor correction banks. Capable of delivering compensation at a rate of 1 second or typically 3-4 seconds maximum, the ACTIVAR can deliver an unlimited number of transient-free operations, is a low-cost replacement for electro-mechanical power factor solutions and is equipped with a comprehensive reporting system. Applications: Hospitals, Data Centers, Extrusion, Office Buildings and other Industrial Applications. |

|

A world leading optimal solution for electrical energy savings and power quality solutions.

The EQUALIZER is the world's fastest real-time power quality enhancement system optimizes all power quality factors and more, for a variety of dynamic fast changing balanced, unbalanced & single phase loads. The EQUALIZER features electronic switching of 5-20 Milliseconds @ 50 Hz, transient-free switching, voltage support, harmonic filtration, flicker & current spike reduction. Applications: Welding Machines, Plastic Injection Molding, Harbor Cranes, Electric Trains, Wind Energy, Generators, Marine Vessels. |

|

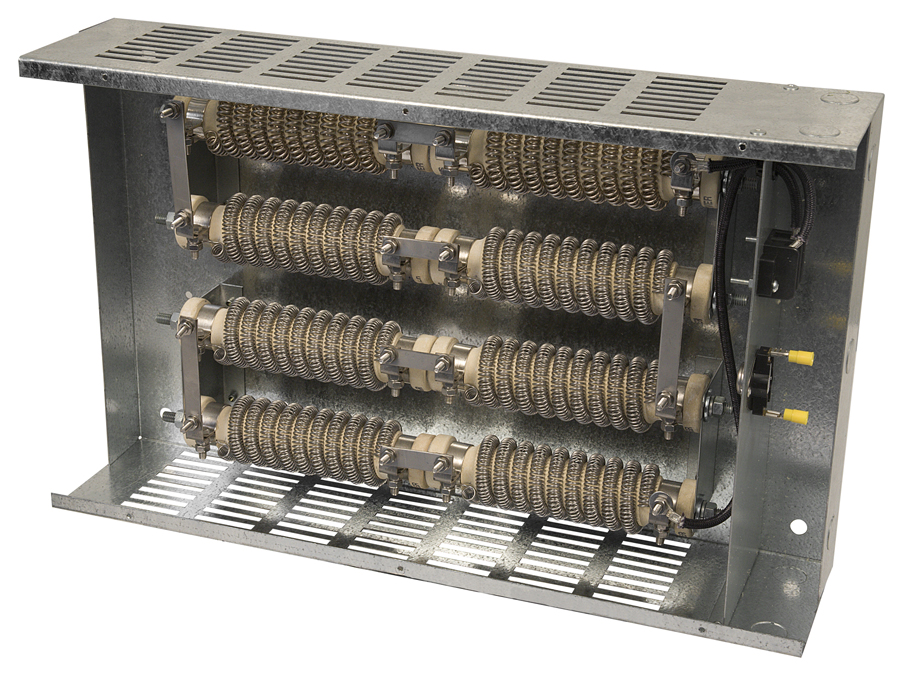

State of the art AC Variable Frequency Drives (VFD) are commonplace today, creating the need for reliable, proven Dynamic Braking Resistors that can be delivered quickly, completely assembled, and ready for convenient installation at the job-site. Dynamic Braking Resistors are used with AC VFD’s to produce a braking torque in the motor during overhauling conditions. The dynamic braking resistor is connected across the DC bus and will see voltages as high as 800 volts.

The drive manufacturer normally determines the power rating (watts) needed to prevent overheating during braking duty. The peak braking current is determined by the specified resistance value. Each drive manufacturer specifies a resistance range with a minimum to prevent overcurrent and damage to the drive and a maximum value to give adequate lower dissipation capability. Standard Nema 1 Enclosure Design Thermal overloads Two Point terminal block Factory Tested Convenient Conduit Knockouts Options: Powder Coated, Nema 3R, Stainless Steel |

|

Motor Control Resistors

A resistor bank is the practical device available for the purpose of protecting motors from the possible overhauling effects of a heavy load. Operators effect changes in motor speed with various loads and operate a bank of magnetic contactors to achieve the desired operation. The contactors change taps on the resistor banks as required to maintain appropriate rotor circuit resistance. Post Glover’s stainless steel grid resistors are an excellent choice for heavy industrial applications because of their durability and dependability in severe environments. Initial information needed for sizing your resistor: Application Horsepower Line voltage Full load amps Starting torque Number of speeds Duty/NEMA class (see tables) For dynamic lowering applications, include manufacturer of control package. |

|

Neutral Grounding Transformers & Resistance Grounding Systems protect power transformers and generators from damaging fault currents. Low resistance grounding of the neutral limits the ground fault current to a high level (typically 50 amps or more) in order to operate the protective fault clearing relays and current transformers. These devices are then able to quickly clear the fault, usually within a few seconds.

The limited fault current and fast response time also prevent over-heating and mechanical stress on conductors. Low resistance grounding resistors are typically rated up to 400 amps for 10 seconds, and are commonly found on medium voltage systems. Ground fault protection for high voltage transformer and generator grounding applications typically require a grounding transformer to lower the voltage reflected to the neutral grounding resistor. Post Glover’s GT product line is designed for applications up to 15kV primary. Secondary voltage is typically 240 V, and resistors are designed according to customer specification. Typical construction is a dry type transformer with a secondary resistor mounted in a common enclosure. |

|

PulserPlus.Net™ – High Resistance Grounding – Systems have gained popularity in the process applications due to their ability to safely continue operation during a single line-ground fault and limit escalation of such a fault from becoming a multi-phase event.

Line to ground faults are the cause of 98% of all plant electrical failures. With increased attention industry-wide to lowering the potentially deadly effects of arcing faults, tackling the problem at its source remains the surest method of increasing your network’s reliability. Downtime costs in both productivity and profits, and Post Glover’s PulserPlus.Net keeps plants running 24/7/365.High resistance grounding benefits have long been recognized when compared to ungrounded or solidly grounded systems. Post Glover’s PulserPlus.Net is the only digital high resistance grounding system with pulsing available today. Available in an OEM kit suitable for mounting in low or medium voltage switchgear cubicles or standard MCC’s, its ease of installation, top-level factory support and overall superiority make this the easy choice when the customer requires a pulsing system for complete ground protection. The pulsing system can be adjusted from 10 to 50 ppm. |

|

Single Phase to Three Phase Converters

Whether you need to power an air compressor, a woodworking shop, or a laser, you'll find the Phasemaster® Type MA rotary three phase converter up to the task. This general-purpose rotary phase converter is a reliable source of true three-phase power. When connected to a 230 volt 1-phase line, the Type MA phase converter produces 3-phase power at its output terminals with each phase shifted 120°. You get a near replica of utility 3-phase power-more economically. Call us for sizing to determine which Type MA phase converter is right for your application. Remember, the most important factor in proper sizing is the application for which your motor is used. The MA phase converter is available in 3 standard configurations. The MA, the MA-A with automatic controls, and the MA-R with a built in disconnect switch. Contact us for assistance. All Phasemaster® rotary phase converters can be tailored to meet your specific application needs with a wide range of accessories including: Automatic controls enable remote monitoring of unattended or cyclical applications. Specify model MA-A Disconnect switches provide simple and fast installation-2 wires in, 3 wires out. Specify model MA-R. Surge protectors safeguard converters from lightning or other surges. Transformers handle special voltage requirements Outdoor enclosures provide maximum weather protection in severe environments. |

|

The Phasemaster® Type DP and DP-A rotary three phase converters offer the same performance and reliability as the general-purpose MA 3-phase converter. Both the manually controlled type DP and the automatically controlled DP-A 3-phase converters have been specially engineered to handle the heavy demands of submersible motors for deep well pumps, duplex lift stations, irrigation systems, fountains and water treatment facilities. The DP-A is specifically designed for unattended applications.

Side-mounted automatic control panel saves energy-turns converter on and off automatically according to load demands. Ideal for duplex pumps operating separately or together. Powers variable frequency drives. |

|

Outdoor pumping or irrigation equipment requires the same reliable 3-phase power as less exposed applications, but the environment calls for a specialized phase converter. The Phasemaster Type PI Rotary 3-phase converter is totally enclosed, enabling it to provide many years of outdoor use.

Runs simultaneously and in any combination: pivot-tower drive motors, end-gun pumps, and submersible pumps. Develops motors' full nameplate horsepower so that pumps will deliver their full-rated flow Convenient side-mounted control box houses input-output terminals and optional disconnect switch, fuses, and controls |